How is the cost of mounting printed circuit boards calculated?

Hi.

There are many unknown things in the world of electronics, and one of them is the cost of mounting printed circuit boards. No one can give an exact answer to this question in advance, and in this article I will help you understand where this price comes from.

To make it more clear, I divided the cost calculation into several options, from which the cost of soldering is added up:

1) Several simple products.

2) A batch of simple products.

3) Several complex products.

4) A batch of complex products.

Each of the points is also divided into manual and automatic installation. And each time there will be a price.

I'll start in order.

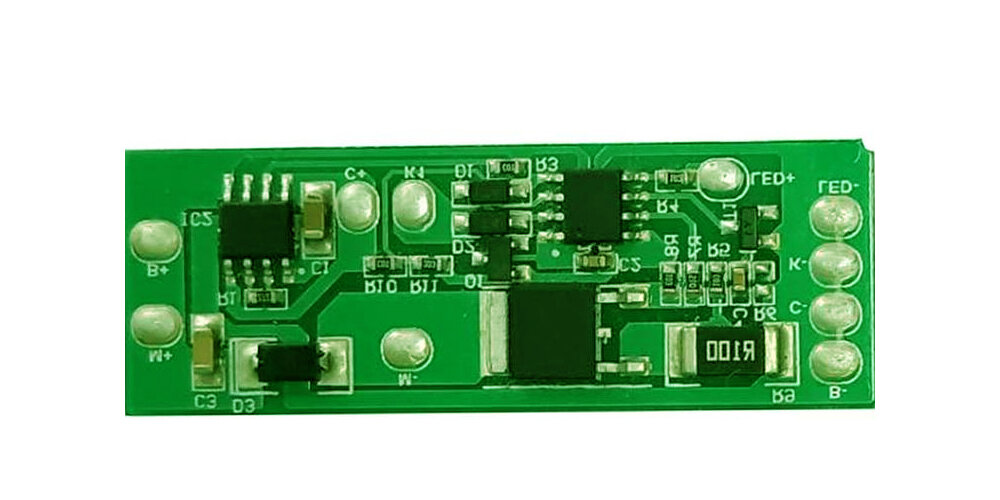

1) Several simple PCB boards.

By simple I mean uncomplicated boards with a small number of components in regular packages, even SMD. To install them, you don’t need any mega-equipment; many of them are soldered at home without any problems. The price is $0.02 on average, because this is still manual work, which is correct to estimate in terms of time and the average values in my practice and many organizations are just $0.02 soldering joint. A stencil is not required if you have enough experience. Without a stencil, such boards are easy to solder.

2) A batch of simple PCB boards.

A batch of simple products can also be assembled by hand, but it is a matter of time and patience. However, if speed is needed, then automatic assembly is indispensable. The machine, in turn, will reduce the cost of soldering simple products to $0.01 - $0.03 per soldering joint, but often the installation time is calculated in several weeks, depending on the workload of production. Ultimately, mass batches are always more economically profitable to solder on automatic lines. But the primary contract manufacturer will have to prepare to solder your board. Ordering stencils, analyzing boards for setting up machines, printers and ovens. Check the data from the BOM file and configure the coordinates of the machine. This can cost up to $0 - $100 for the first order. Almost no one does equipment setup for free. Don't be intimidated by this service - it's really needed.

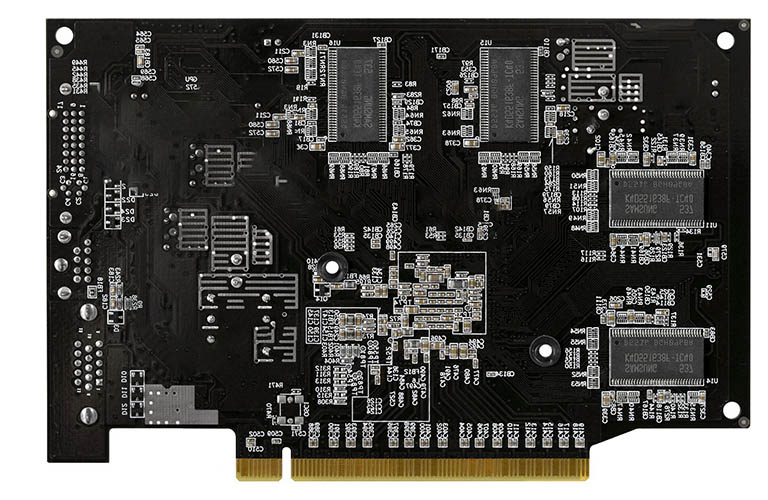

3) Several complex PCB boards.

If you have experience and practice, you can assemble almost any product by hand, but not many people want to do this and immediately negotiate with the manufacturer. With manual soldering, you can save time and there is no need to pay for preparation for production. With automatic soldering, the time is several weeks and the cost of initial preparation is required. The price per point ranges from $0.01 to $0.08 per point, depending on the complexity of the board.

4) A batch of complex PCB boards.

Don't even think about it - just automatic SMT mounting.

What should you pay attention to when choosing a manufacturer?

If you are applying somewhere for the first time, it is very difficult to say how well this production can assemble your boards. Everyone got burned. The cost of mistakes is just different. Some productions never admit their mistakes, some correct mistakes without problems. Price, time and reputation are perhaps the main set of parameters to choose from.

Prepare production requirements in advance if you understand this:

- It is advisable to indicate the thickness of the stencils, if you are not the one ordering them; many manufactories deal with this issue on their own.

- You need to indicate exactly the type of paste you want to solder your boards with. Based on this, whether it is necessary to wash the boards or not, sometimes it is necessary to wash them. Control after soldering (not everyone can do this).

PCB Fabrication companies list - https://smt-industry.com

Thank you so much for reading!